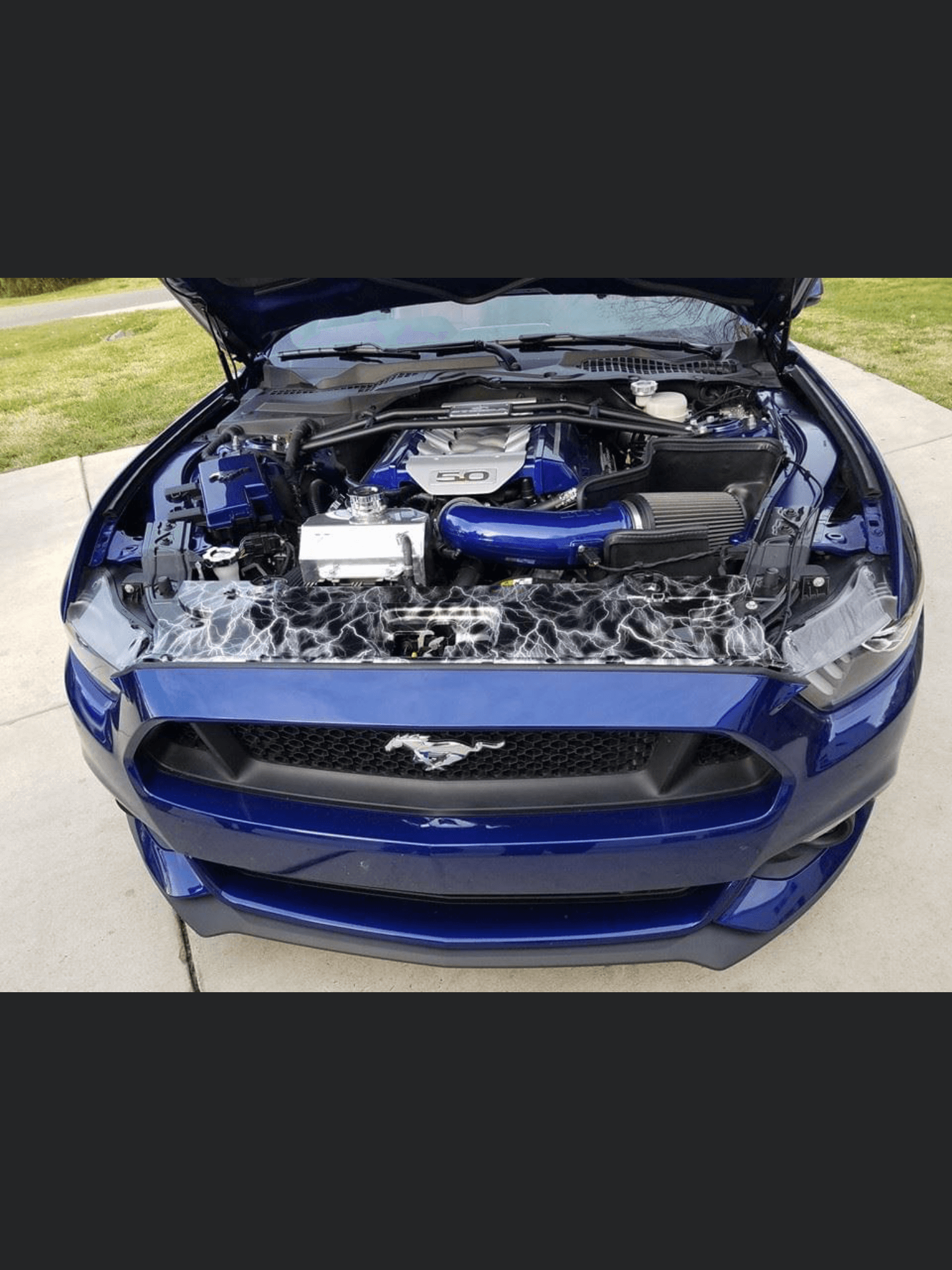

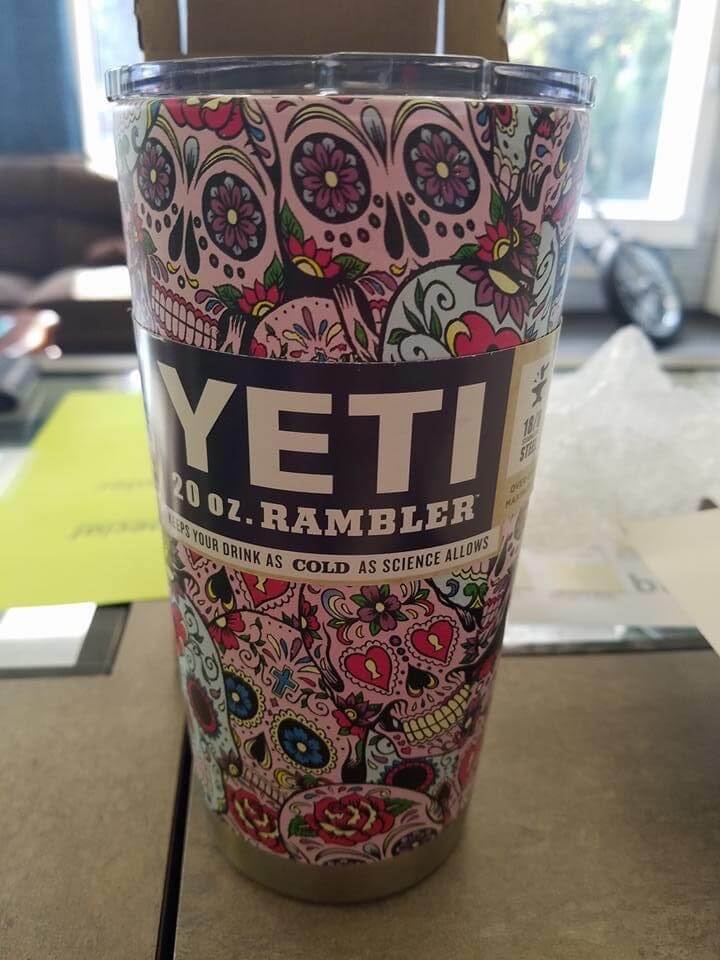

Water transfer printing, also known as Hydrographics, immersion printing, water transfer imaging, hydro dipping, watermarbling, cubic printing, is a method of applying printed designs to three-dimensional surfaces. We have the ability to apply graphic designs to firearms, safety equipment such as sports and automotive helmets, automobile and marine parts, household items like metal cups, and many more types of hard surfaces. The inks we use to print our patterns are developed and tested using Xenon Arc testing, ensuring the coating retains its color and integrity in prolonged sun exposure and other environment conditions. Our clear coat is automotive grade, which is also designed to withstand nature and time. Have a great idea? Contact us!

Frequently Asked Questions

What types of surfaces can you coat?

A wide variety of flat or 3-D shapes and manufacturing materials (plastics, metals, glass, wood, etc.) can be decorated with Water Transfer Printing technology. We like to let our product speak for itself. Some of our largest clientele are automobile, boat, and firearm manufacturers who demand the highest standards of quality and durability. Many parts that are decorated using our materials spend most their lives in direct sun exposure, such as boat instrument panels.

What is the process for hydrographic coating?

The process utilizes a water-soluble film that contains complex patterns printed in ink. The film dissolves in the water and leaves the ink on the surface. In the typical process, the item is first coated with a primer or an adhesion promoter. After the primer is dry, a base-coat paint is applied which controls the hue of the pattern. Many hydrographic films are transparent which means you can achieve unique designs by customizing the base coat colors. For example, wood grain films often utilize a brown base coat and many camouflage patterns use a required base coat color to maintain the integrity of the pattern. After the base coat is applied, the item is ready for decorating. The film is activated. The item is then dipped into the water and the ink wraps around it. Excess PVA residue is then washed off, the part is dried, and a clear top coat is applied.

How much does it cost?

Contact us for a quote by using the form on our website.

Is it permanent? Can you remove or redo it?

Yes, of course you can redo the water transfer printing. Items that do not meet your quality requirements can be painted and dipped again.

Examples of Hydrographics

LET’S TALK! We would love to help you with your project or idea. Contact our friendly, innovative and creative team of powdercoating/hydrographics experts via phone or email!